This article contains sponsored content.

Guest Post By NARA Member, Eric Schnakenberg, Area Manager at Chem Aqua Midwest

There may be gold in your water pipes.

Water management, done correctly, can manifest many dollars for rendering facilities both from saved utility costs and marketing opportunities from water savings achieved.

There is no secret that energy costs are soaring. Therefore, it’s more important than ever to review your water treatment program. Each facility may have different options but here are some points to check to look for sustainability gains.

BOILER SCALE

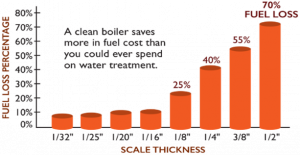

Scale buildup prevents heat transfer from your fuel source to the water in your boiler. Even small amounts have exponential effects.

Removing or eliminating scale in the boiler may yield savings for your facility. You may need to open the boiler to determine current scale buildup, but the results speak for themselves. Annual inspections are a great time to assess scale removal needs.

CYCLES OF CONCENTRATION

CYCLES OF CONCENTRATION

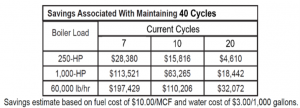

On top of scale concerns, we need to keep an eye on Cycles of Concentration. (CoC) This is how many times we can use the water in the boiler before it has to be replaced. Obviously, the more we can use it, the less it costs. Heating cold tap water is expensive. Obviously, reusing heated/treated water is far better. Tracking CoC yields savings for your facility. The best way to do this is with automated blowdown controls, but it can be managed manually with regular testing protocols. Establish a plan to control Cycles of Concentration in your facility.

(**Number of optimal cycles for your system will vary depending on many factors)

(** 40 cycles or higher achieved with Reverse Osmosis Water)

AIR SCRUBBERS

Air Scrubbers use water the entire time your system is in operation so it’s no surprise these machines can drastically help or hurt water and energy usage goals. Depending on the need there are several options to treat these systems to help keep odors under control and/or keep the system clean. Using soft water, or simply managing your flow rates based on need can save thousands of gallons per year and dozens of hours in labor costs/downtime. As a large water user in most rendering facilities, these systems are worth the attention.

As you can see SMALL improvements in your water treatment program can have HUGE results to the bottom line.

Minimal man hours will more than pay for themselves in returned costs. Developing a great water plan takes some time and commitment, but there are few places to see such exponential returns from your efforts. Automation helps, but there are gains to be had without major capital investment in your facility.

Managing your water may measure produce liquid gold (dollars) for your facility.

Take a look at these 3 areas for easy gains:

Establish a water plan/protocol for your facility, gain the cost savings, then market to your customer the savings and sustainability increases. Who wouldn’t want to hear that you saved millions of gallons of water and thousands of pounds of fuel?